Exam: Power Stow Foundations

Duration

3-4 Minutes

Training Type

Initial Training & Recurrent Training

IATA Standard

IATA AHM 1110, Edition 46 & IATA IGOM, Edition 15

Description

This assessment verifies the trainee's understanding of all Power Stow Equipment 101 foundational lessons through a 10-question multiple-choice exam. The exam reinforces operational controls, height adjustment procedures, walkaround inspection requirements, and safety knowledge required for compliant cargo hold operations.

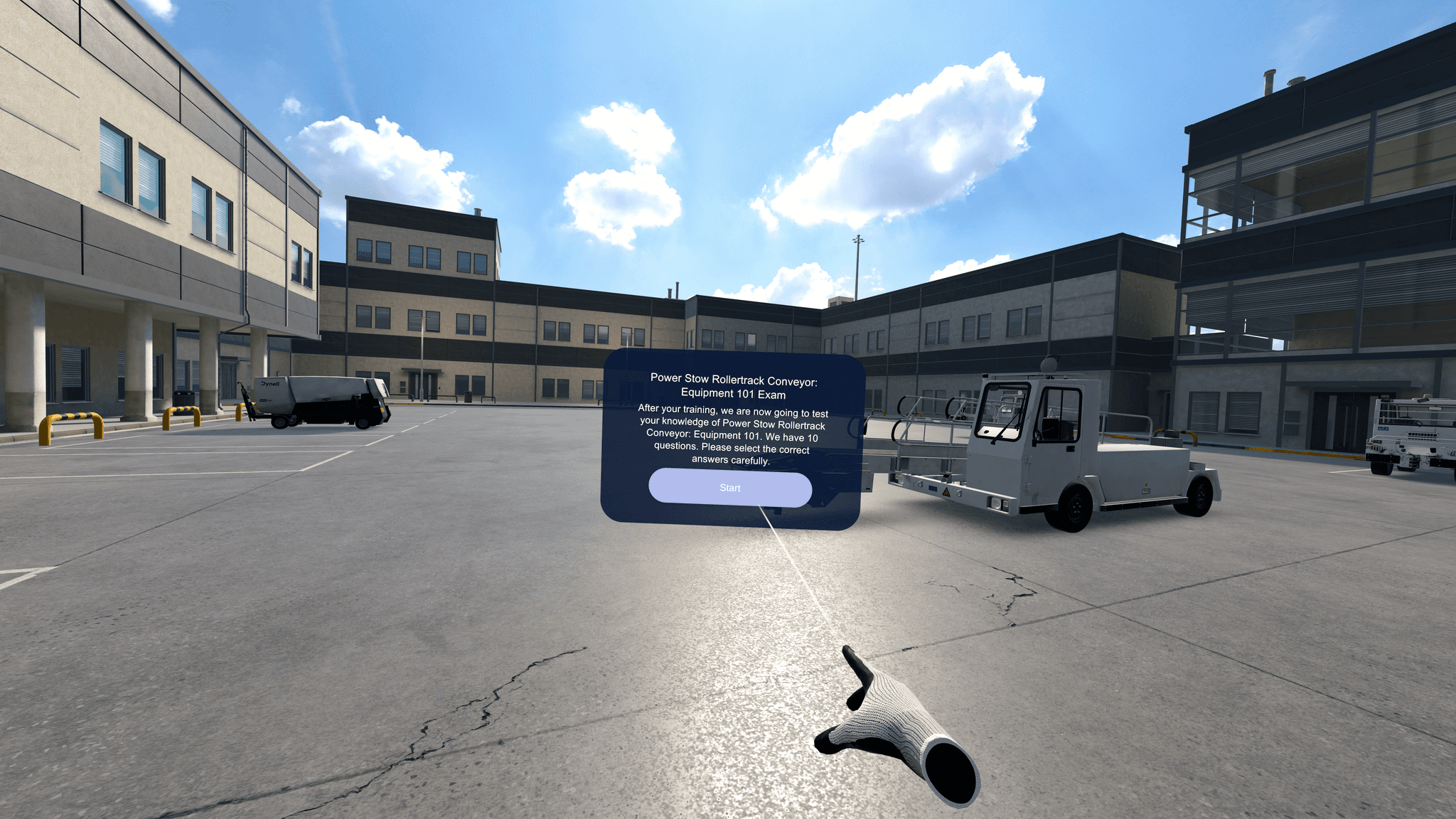

Exam Overview

- 1Introduction to the exam and its purpose

- 2Series of 10 questions covering all foundational Power Stow lessons

- 3Immediate feedback for each question to reinforce correct reasoning

- 4A minimum score of 80% (8 correct answers) is required to pass

Skills Acquired

- Recall the primary function and operational controls of the Power Stow Rollertrack Conveyor system

- Identify correct procedures for extending, retracting, starting, stopping, and adjusting Power Stow operations

- Demonstrate understanding of emergency stop functionality and speed/direction control mechanisms

- Confirm theoretical readiness before advancing to operational Power Stow training

Exam Procedure

- The exam consists of 10 questions, each offering three to four answer options requiring selection of one correct answer.

- Topics span Power Stow Rollertrack Conveyor Basics and Walkaround lessons, covering system purpose, movement handle operation, toggle switch functions, height adjustment, emergency stops, speed and direction control, and pre-operational inspection procedures.

- Each correct response is confirmed instantly; incorrect selections trigger corrective feedback.

- Upon answering all exam questions, if at least 80% of the answers are correct, a short summary confirms that the trainee has successfully demonstrated theoretical understanding of Power Stow Rollertrack Conveyor operations; otherwise, the exam is not considered successfully completed.

Sample Exam Questions

- What is the primary purpose of the Power Stow Rollertrack Conveyor system?

- How do you extend or retract the Power Stow Rollertrack Conveyor?

- How do you start and stop the Power Stow?

- How do you adjust the height of the front of the Power Stow?

- What happens when you press an emergency stop button?

- How do you increase the speed of the Power Stow Rollertrack Conveyor?

- How do you change the direction of the Power Stow Rollertrack Conveyor?

- What is the purpose of the walkaround?

- When should you perform a Power Stow Rollertrack Conveyor walkaround?

- What must you do if you identify a faulty component during the walkaround?