Walkaround

Description

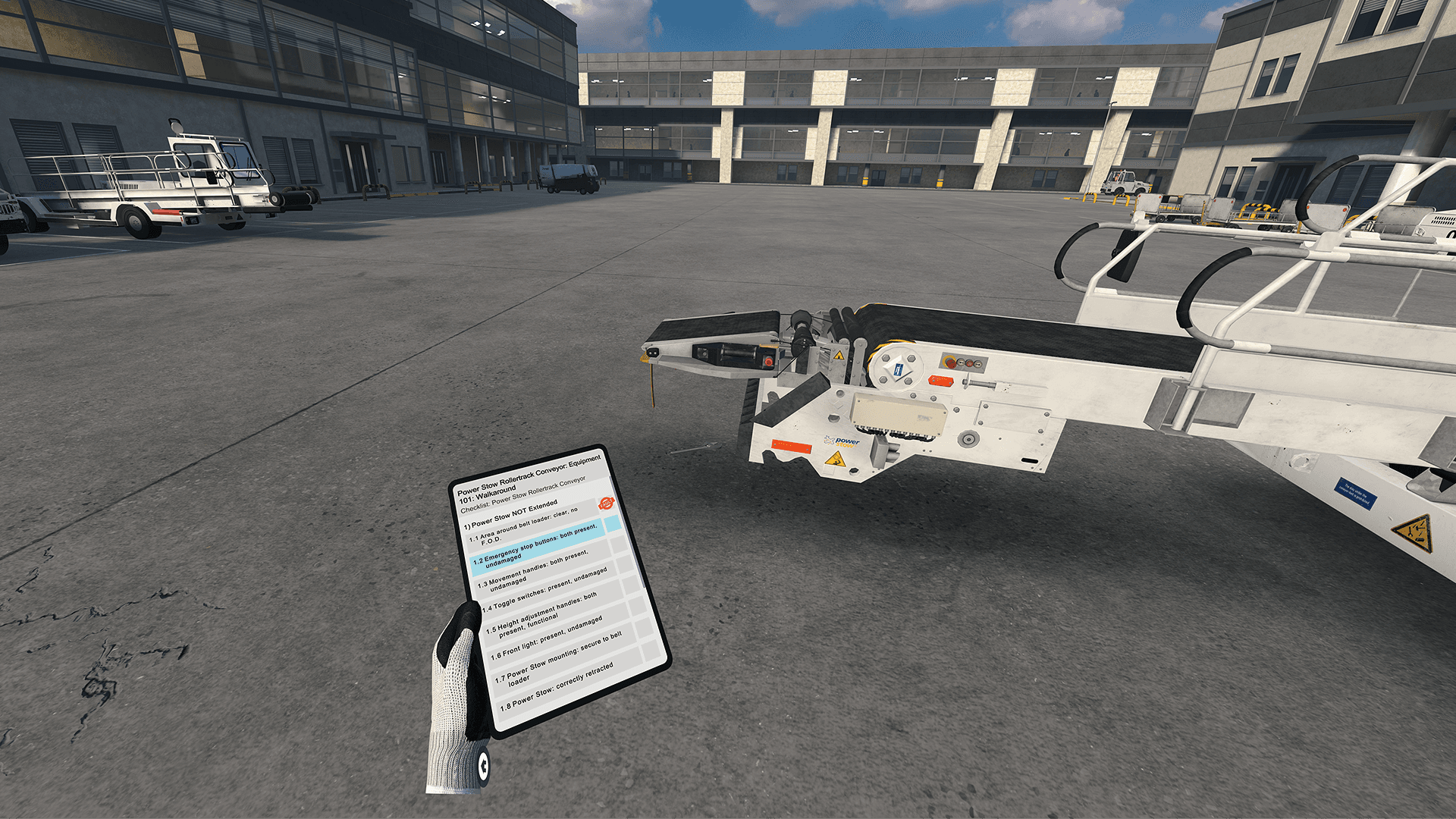

This lesson trains the pre-operational walkaround inspection required before any Power Stow operation. Trainees use a structured checklist to systematically inspect the rollertrack conveyor in both retracted and extended configurations. The exercise emphasizes identifying equipment faults that could compromise safe baggage handling operations.

Lesson Overview

- 1Receive the walkaround checklist covering Power Stow controls, safety features, and structural components

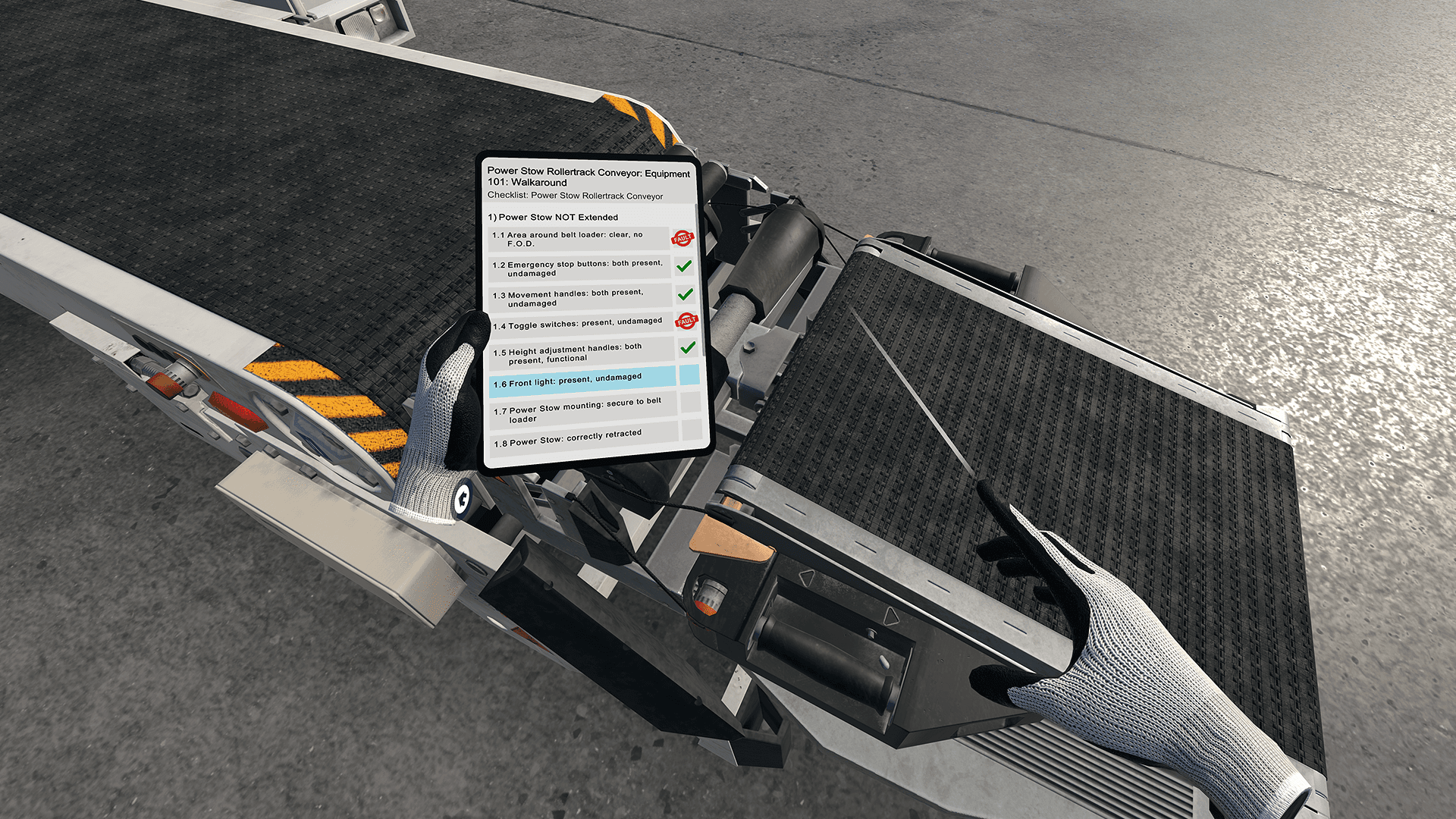

- 2Inspect the non-extended Power Stow including area clearance, emergency stops, movement handles, toggle switches, height adjustment handles, front light, mounting security, and retraction status

- 3Inspect the extended Power Stow including roller track surface clearance, belt surface condition, roller presence and functionality, and frame structural integrity

- 4Mark each checklist item as OK or identify visible faults, receiving immediate feedback on inspection accuracy

Skills Acquired

- Perform systematic pre-operational walkaround inspections

- Identify safety-critical faults

- Recognize F.O.D. hazards on equipment surfaces and surrounding areas

- Detect structural damage that compromises equipment integrity

- Understand the safety significance of each inspection point for preventing equipment failures and personnel injuries

Lesson Procedure

- The lesson starts in a GSE parking lot. The trainee is equippend with a checklist covering several Power Stow inspection items; the first section covers the non-extended Power Stow positioned in front of the trainee.

- The surrounding area is inspected for foreign object debris including baggage, tools, or cargo straps on the ground near the equipment.

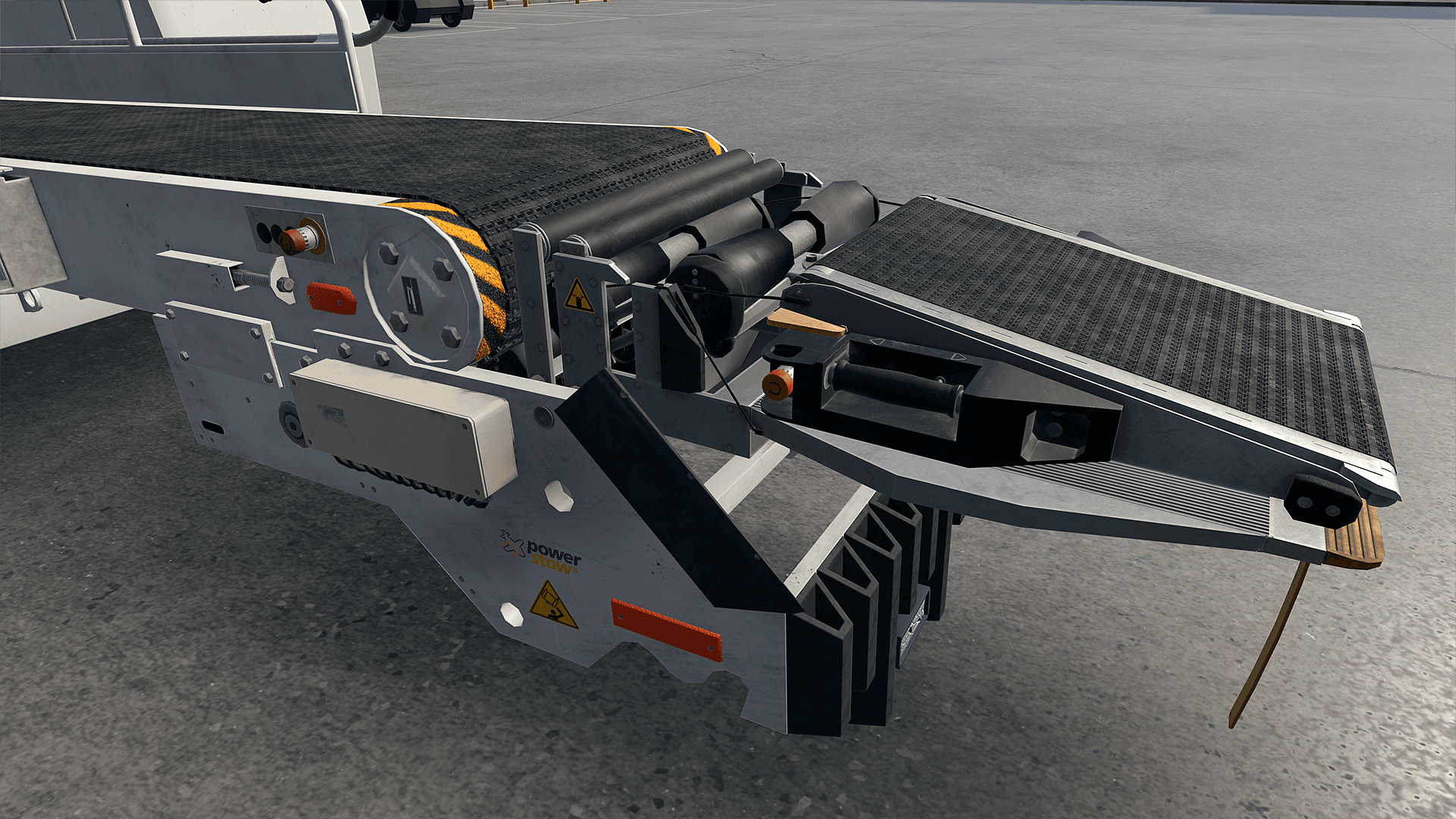

- Both emergency stop buttons are inspected on each side for housing damage or button defects.

- Both movement handles are checked to verify grips are securely attached and not bent or broken.

- Toggle switches located behind the movement handles are verified present and intact.

- Both height adjustment handles are inspected to confirm presence and secure attachment.

- The front light is checked to verify presence and housing integrity.

- Mounting points are visually confirmed to show no gaps or looseness securing the Power Stow to the belt loader frame.

- The Power Stow retraction status is confirmed with the roller track locked in transport position.

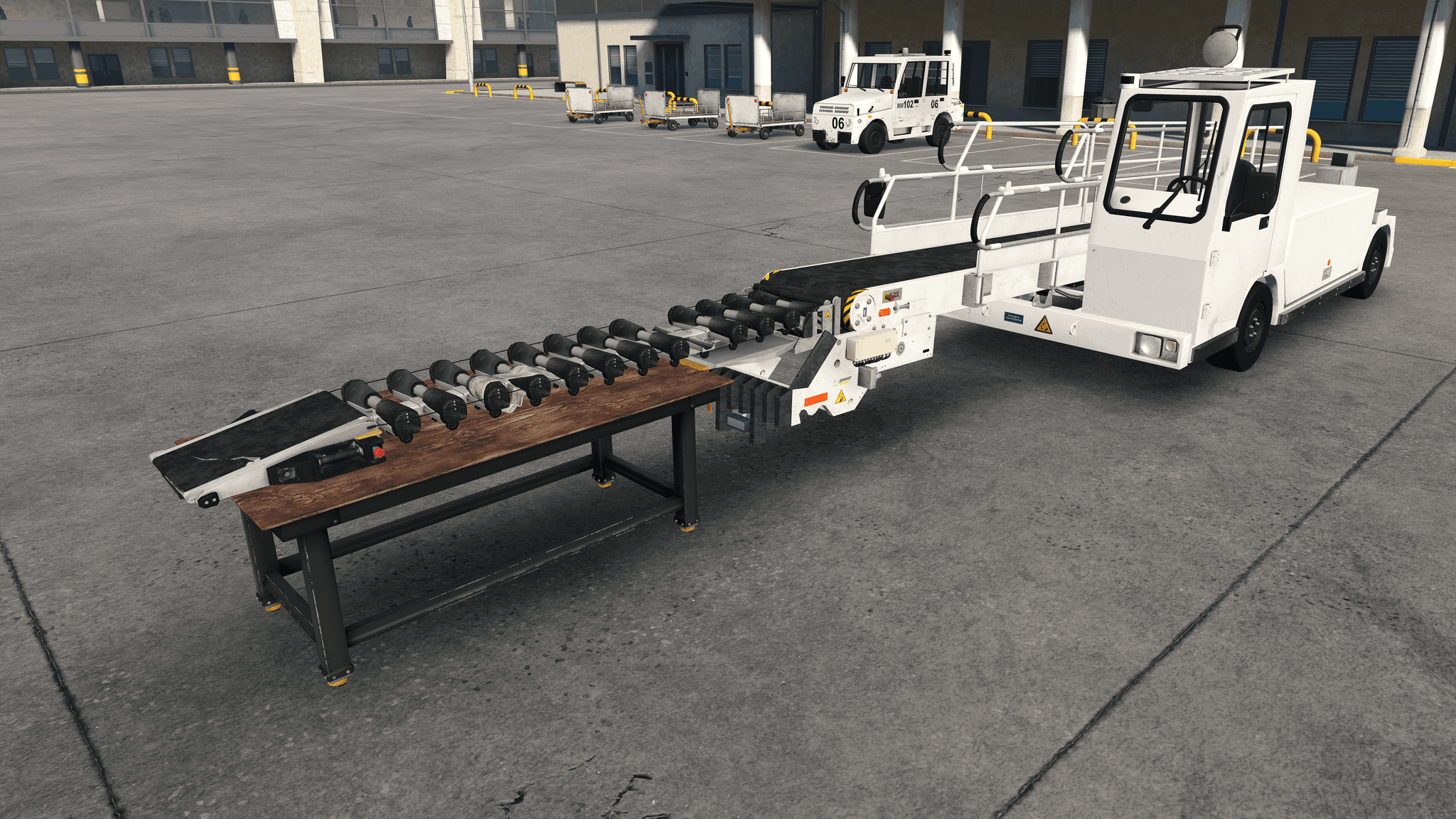

- The environment transitions to an extended Power Stow configuration for the second section.

- The extended roller track surface is inspected to ensure no baggage, cargo straps, or foreign objects remain on or between roller elements.

- The Power Stow belt surface is examined along its length for cuts, tears, or excessive wear.

- All rollers along the roller track are inspected to confirm presence and verify none are broken or detached.

- The frame structure including support beams is examined for visible cracks or deformation.

- Each checklist item is marked OK if acceptable or the visible fault is identified; incorrect assessments trigger error feedback requiring re-inspection.

Safety Scenarios & Learnings

F.O.D. near equipment

Reinforces that foreign objects must be identified and removed before operations to prevent equipment damage and safety hazards.

Reinforces that foreign objects must be identified and removed before operations to prevent equipment damage and safety hazards.

Damaged emergency stop button

Demonstrates that cracked emergency stop housings compromise emergency safety systems and prevent immediate operation shutdown.

Demonstrates that cracked emergency stop housings compromise emergency safety systems and prevent immediate operation shutdown.

Broken movement handle grip

Emphasizes that missing grips prevent safe manual operation of extension and retraction.

Emphasizes that missing grips prevent safe manual operation of extension and retraction.

Missing toggle switch as

Reinforces that without operational controls the Power Stow cannot function and must be reported faulty.

Reinforces that without operational controls the Power Stow cannot function and must be reported faulty.

Missing height adjustment handle as

Shows that broken handles prevent safe height adjustment operations.

Shows that broken handles prevent safe height adjustment operations.

Damaged front light

Highlights that damaged lighting creates visibility hazards in low-light cargo hold conditions.

Highlights that damaged lighting creates visibility hazards in low-light cargo hold conditions.

F.O.D. caught between rollers

Reinforces that objects caught in the roller track create FOD hazards and damage risk during operation.

Reinforces that objects caught in the roller track create FOD hazards and damage risk during operation.

Torn belt surface

Shows that belt damage catches baggage and worsens rapidly during operations.

Shows that belt damage catches baggage and worsens rapidly during operations.

Missing rollers

Highlights that missing rollers cause belt misalignment and damage to both equipment and baggage.

Highlights that missing rollers cause belt misalignment and damage to both equipment and baggage.

Cracked frame support beam

Reinforces that structural cracks compromise the entire system's integrity and require immediate reporting.

Reinforces that structural cracks compromise the entire system's integrity and require immediate reporting.

Gallery