Walkaround

Description

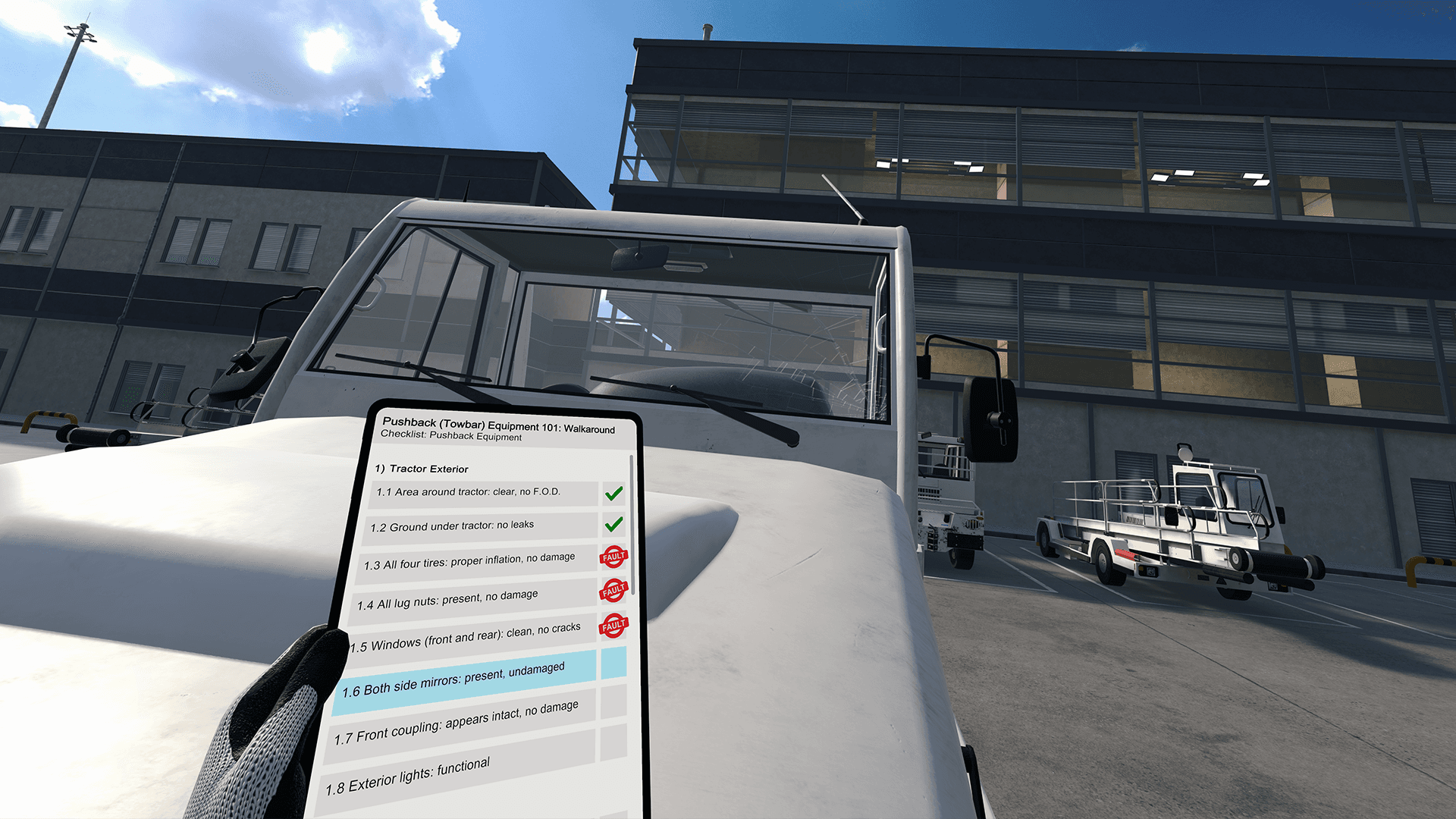

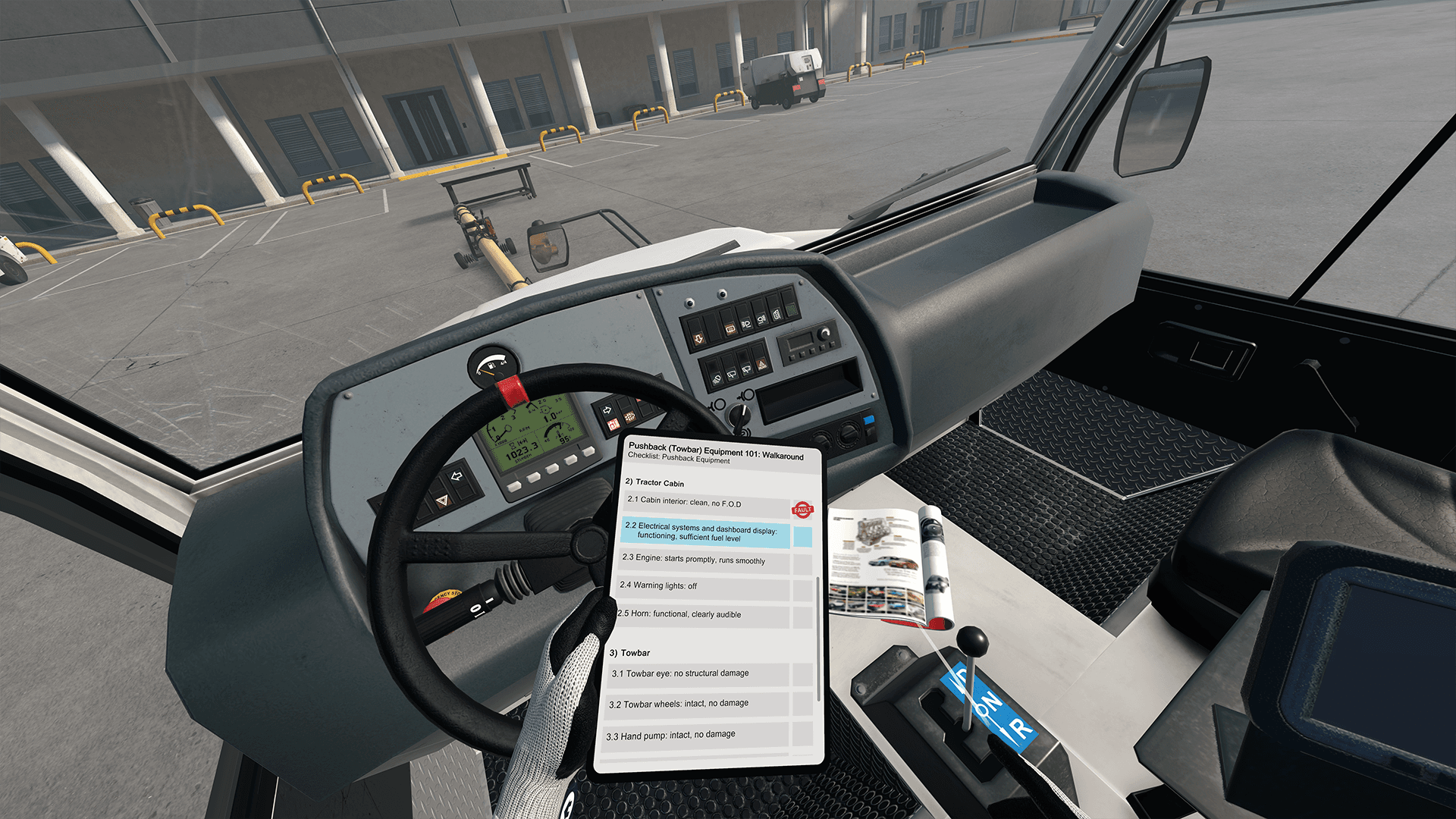

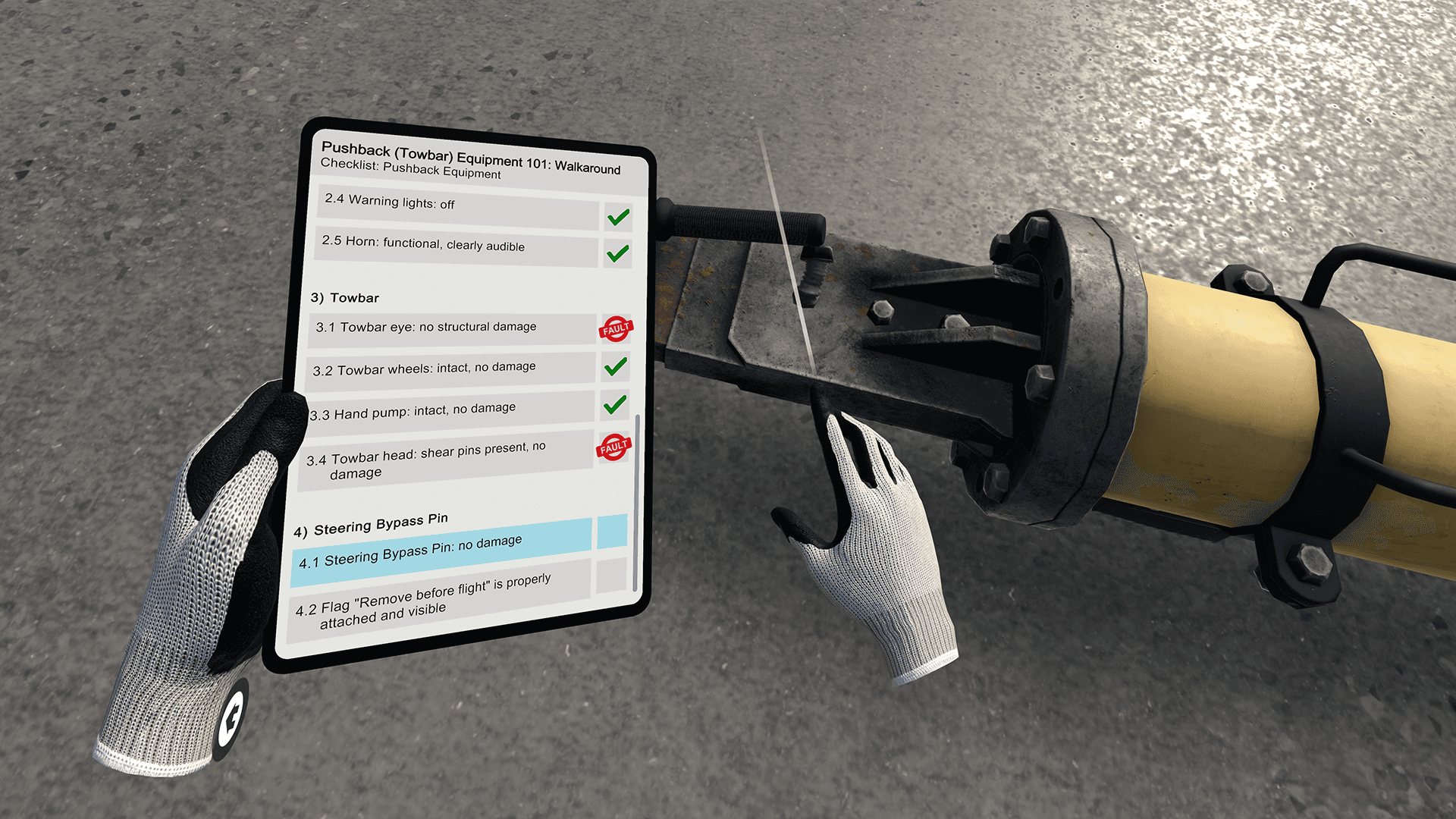

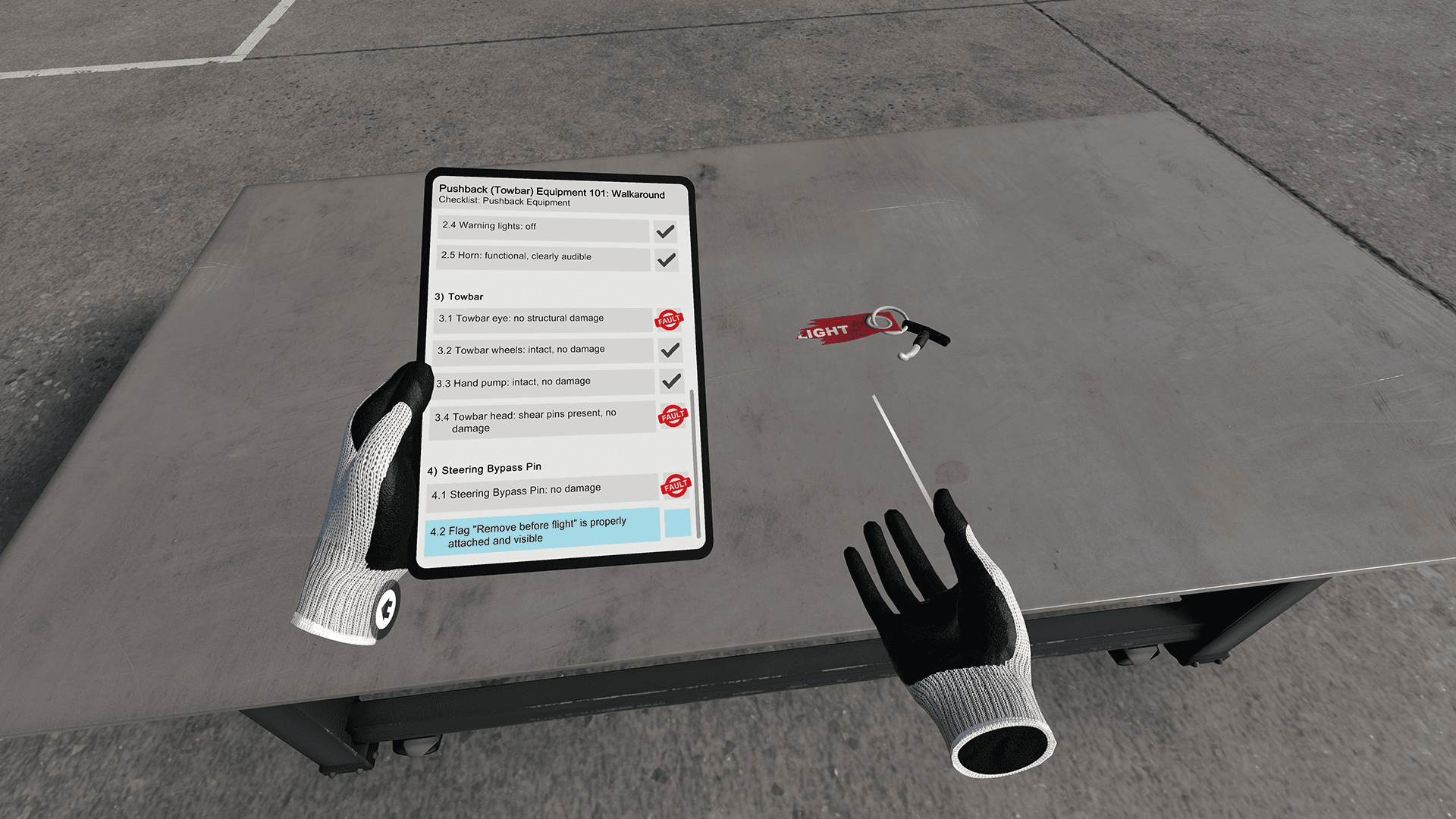

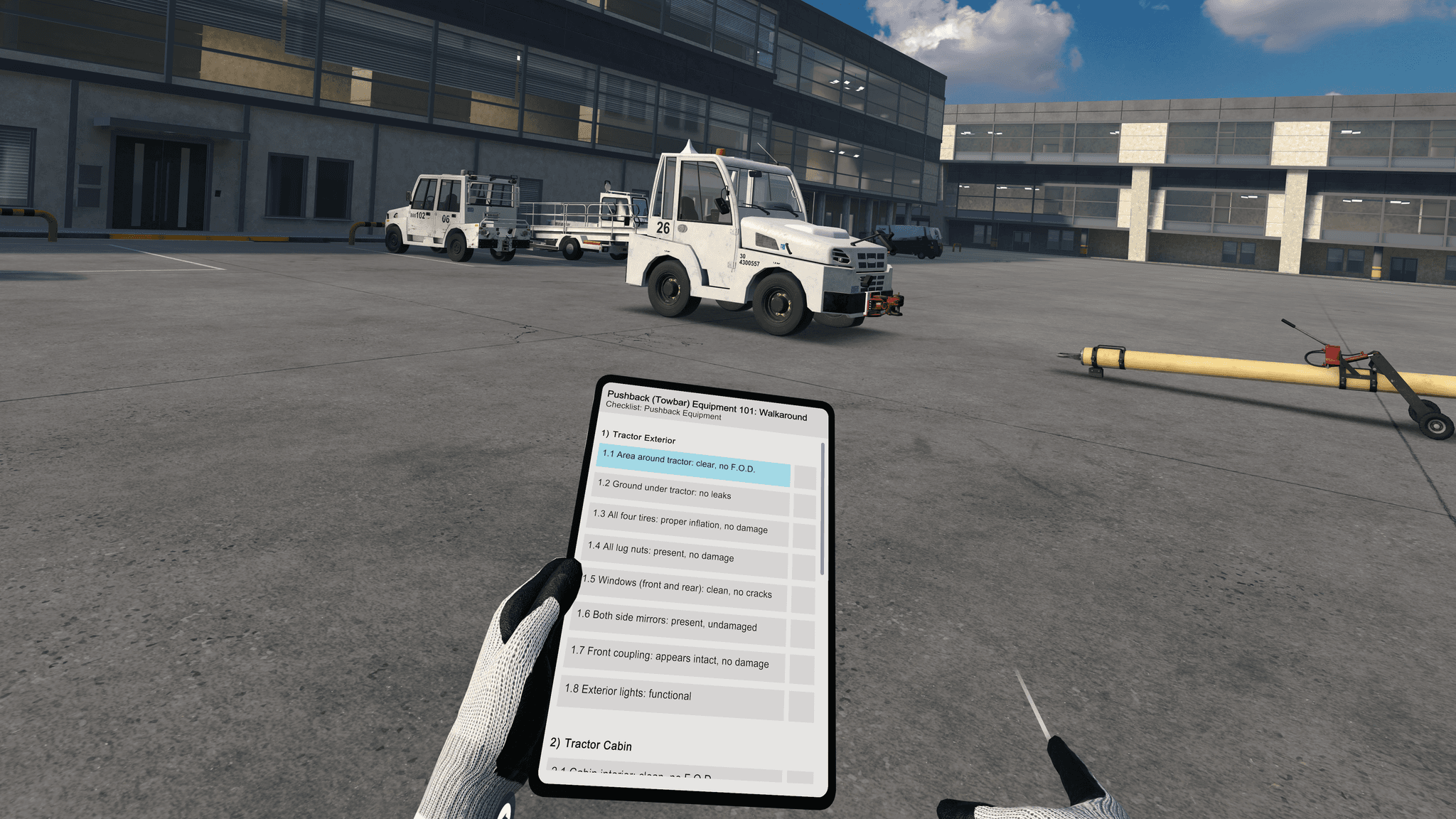

This lesson teaches a complete pre-operational walkaround inspection of pushback equipment to confirm safety and operational readiness before shift operations. Trainees work through a checklist-based inspection flow, independently locating each component and marking it as OK or FAULTY.

Lesson Overview

- 1Introduction to the checklist-based walkaround and how to mark items OK or FAULTY

- 2Complete the checklist section-by-section (Tractor Exterior, Tractor Cabin, Towbar, Steering Bypass Pin)

- 3Validate inspection decisions and correct missed faults when an item is wrongly marked OK

- 4Finish the full inspection loop and confirm the equipment is either ready or must be removed from service

Skills Acquired

- Perform a complete walkaround using a structured checklist

- Independently locate inspection points and make correct serviceability decisions

- Identify critical visible defects (e.g., F.O.D, leaks, damaged tires/windows, towbar defects) before operation

- Apply consistent “inspect → decide → validate” behavior, including re-checking when a fault is missed

Lesson procedure

- The lesson starts with the trainee placed in front of the pushback tractor in the training parking lot, with the towbar and a steering bypass pin nearby.

- The trainee receives a checklist panel and completes the walkaround, with each checklist item activating one after the other.

- When an item activates, the trainee hears a detailed voice-over describing what to check and why. The trainee then independently finds the component in the scene, visually inspects it, and marks the checklist item as OK or FAULTY.

- If the trainee correctly identifies a fault, the item is stamped as faulty on the checklist. If the trainee misses a fault and marks it OK, an error prompt is triggered and the trainee must inspect again before continuing.

- The walkaround proceeds through the checklist sections in order, until all items are completed.

- The lesson concludes by reinforcing that a full checklist-based walkaround is required before operating any equipment, and that any confirmed fault means the equipment must be reported and not used.

Safety Scenarios & Learnings

Area around tractor not clear (F.O.D present)

Reinforces that debris near the tractor must be identified and cleared/reported before operation.

Reinforces that debris near the tractor must be identified and cleared/reported before operation.

Fluid leak under the tractor

Highlights that leaks indicate unserviceable equipment and must be reported before use.

Highlights that leaks indicate unserviceable equipment and must be reported before use.

Deflated tire

Demonstrates unsafe handling risk; reinforces checking tires for serviceability before driving or towing.

Demonstrates unsafe handling risk; reinforces checking tires for serviceability before driving or towing.

Missing lug nuts

Shows wheel security risk; reinforces checking wheel hardware before operation.

Shows wheel security risk; reinforces checking wheel hardware before operation.

Cracked window

Reinforces visibility and structural safety checks before use.

Reinforces visibility and structural safety checks before use.

Broken side mirror

Reinforces that missing/damaged mirrors reduce safety and must be reported.

Reinforces that missing/damaged mirrors reduce safety and must be reported.

Defective headlights/exterior lights

Reinforces importance of visibility-to-others on the ramp.

Reinforces importance of visibility-to-others on the ramp.

F.O.D inside the cabin

Reinforces that loose items in the cabin create distraction and hazard; cabin must be clear.

Reinforces that loose items in the cabin create distraction and hazard; cabin must be clear.

Empty fuel gauge / low fuel

Demonstrates operational interruption risk; reinforces checking fuel status before shift use.

Demonstrates operational interruption risk; reinforces checking fuel status before shift use.

Crack in the towbar eye

Highlights structural failure risk; reinforces inspecting towbar connection points for cracks/damage.

Highlights structural failure risk; reinforces inspecting towbar connection points for cracks/damage.

Broken towbar wheel suspension

Reinforces that damaged towbar running gear is unsafe and must be reported.

Reinforces that damaged towbar running gear is unsafe and must be reported.

Broken/missing shear pin at the towbar head

Reinforces that towbar head hardware must be complete and serviceable.

Reinforces that towbar head hardware must be complete and serviceable.

Bent steering bypass pin

Reinforces correct tool condition checks; damaged pins must not be used.

Reinforces correct tool condition checks; damaged pins must not be used.

Damaged “Remove Before Flight” flag on the bypass pin

Reinforces that identification/flag visibility matters and must be intact.

Reinforces that identification/flag visibility matters and must be intact.

Gallery