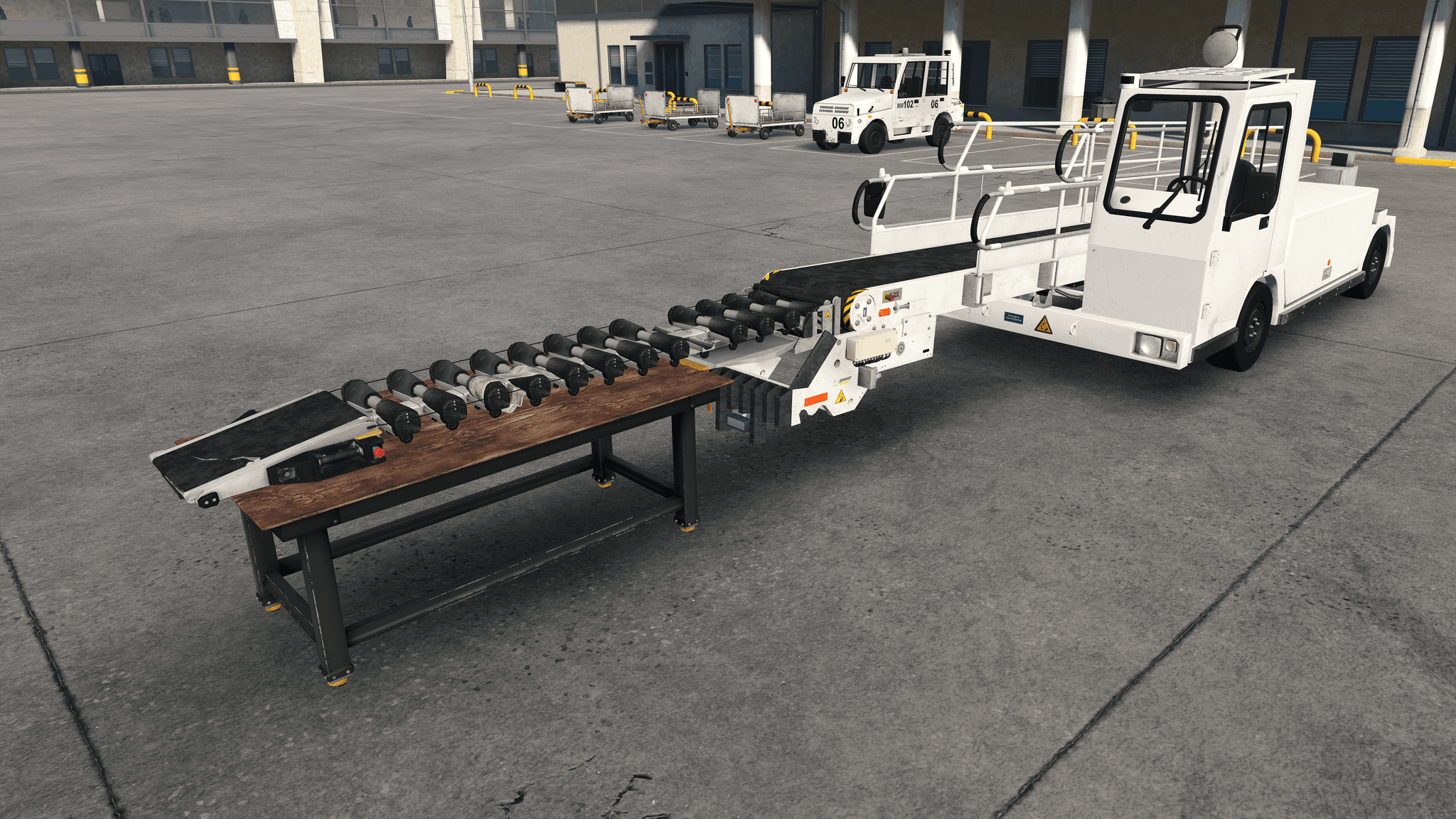

Power Stow Rollertrack Conveyor

Practical Power Stow Rollertrack Conveyor Training in Virtual Reality: Learn the rollertrack conveyor system through complete operation observation, component identification, and systematic walkaround inspections.

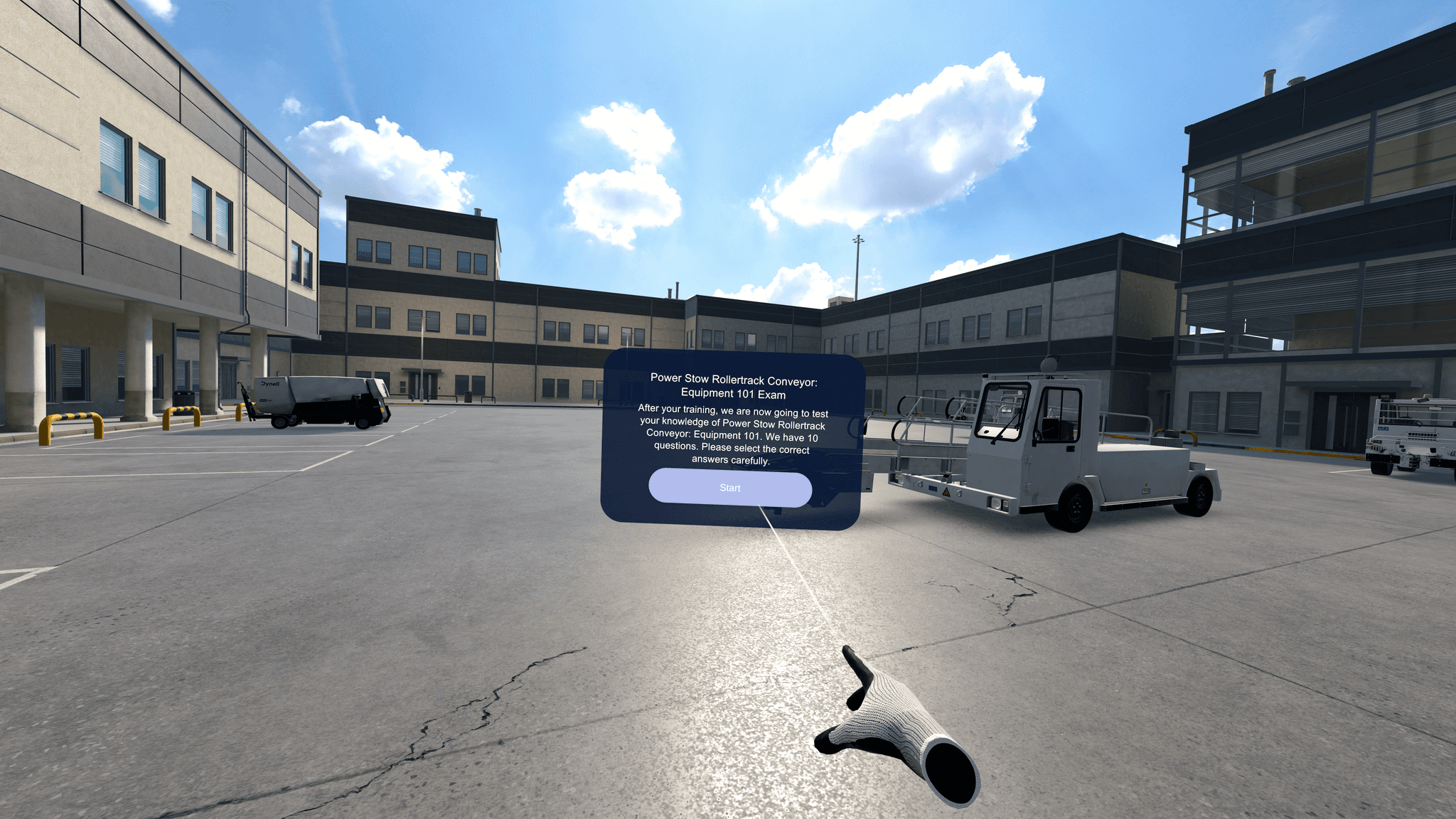

Module with 6 lessons 3 of which are available to play right now.

Designed for ground handling operators: from new starters to professionals, covering foundational pushback training today, with operational trainings and recurrent modules coming soon.

In depth Power Stow Power Stow Rollertrack Conveyor training with 21 learning minutes right now, and many more to follow.

Our training is already available in 4 languages with more to come.

Training Content

All use cases covered by Draxon Pushback VR Training

Learning Outcomes

Lessons

In use at innovative airports and trusted by industry leaders

Real Results, Real Feedback

Hear from industry leaders transforming their training programs.

“You put on the headset and it is like you are on the ramp. It is very easy to use and feels just like real-life training.”

“Draxon is easy to use and extremely efficient. Our trainees enjoy the VR trainings, and the knowledge really sticks.”

“Every step is explained clearly and in detail, making it easy to learn the procedures before going outside. It really bridges the gap between theory and practice”

Highlights of the Power Stow Rollertrack Conveyor Training Module

Get to know the key outcomes of the Power Stow Rollertrack Conveyor VR training.

Complete Operation Observation:

Trainees observe a full Power Stow Rollertrack Conveyor operation cycle from inside the aircraft cargo hold—watching extension, activation, baggage transport, direction changes, speed adjustment, height adjustment, and retraction. They examine all key components including movement handles with light sensor activation, toggle switches for multi-function control, height adjustment handles, and dual emergency stops, building comprehensive understanding of system capabilities and controls before operational use.

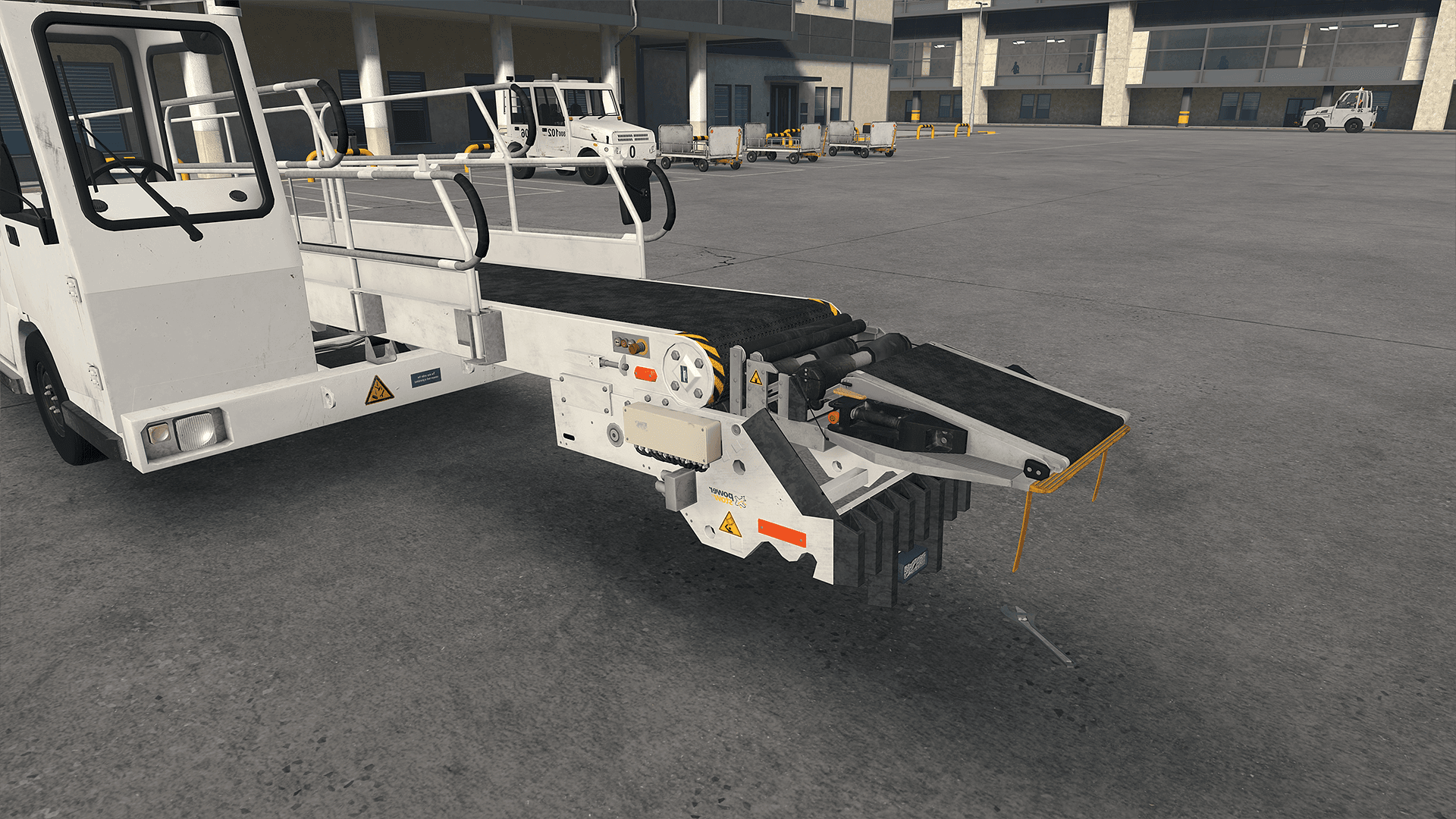

Systematic Pre-Operational Inspection Training:

The structured walkaround covers both retracted and extended Power Stow Rollertrack Conveyor configurations using a detailed checklist, training trainees to identify safety-critical faults including damaged emergency stops, broken controls, missing components, foreign object debris, torn belt surfaces, missing rollers, and structural frame cracks—establishing consistent inspection discipline that prevents equipment failures and ensures cargo hold safety before every shift.

Meeting the Highest Industry Standards

IATA

Built to meet IATA’s global operational and safety requirements, supporting standardized and efficient aviation practices.

EASA

Aligned with EASA safety and regulatory standards to ensure consistent, reliable, and compliant aviation training.

GDPR

Designed with full GDPR compliance, ensuring secure data handling, privacy protection, and trusted information management.

Ready to start Powet Stow training?

Get everything you need to roll out VR training for your teams.

Questions? We have answers:

What skills are gained in the Pushback (Towbar) VR Training module?

The Power Stow Rollertrack Conveyor VR Training module teaches cargo handling staff the foundational knowledge required to work safely with the Power Stow system. Trainees observe a complete Power Stow operation cycle from inside an aircraft cargo hold, learning how the system extends, transports baggage, adjusts direction and speed, raises and lowers for height adjustment, and retracts. They learn to identify all key components including movement handles with light sensor activation, toggle switches for start/stop and direction/speed control, height adjustment handles, and emergency stop buttons. Trainees practice systematic pre-operational walkaround inspections using structured checklists, identifying safety-critical faults such as damaged emergency stops, broken controls, missing components, foreign object debris, torn belt surfaces, missing rollers, and structural frame cracks.

Are the Power Stow Training lessons videos to watch?

No. The Basics lesson includes observational learning where trainees watch a colleague demonstrate the complete Power Stow operation cycle from inside the cargo hold, followed by close examination of components. The Walkaround lesson is fully interactive—trainees perform the inspection themselves using a tablet-based checklist, locate and inspect each component, and identify faults, receiving immediate feedback on their assessments. This combination of observation and hands-on practice builds both understanding and procedural discipline.

Is the Pushback (Towbar) VR Training applicable for initial training?

Yes. The module is designed as foundational preparation for personnel who will work with the Power Stow system. It introduces the equipment's purpose, operational controls, and systematic inspection requirements in a safe environment before trainees move to supervised cargo hold operations.

Is the Pushback (Towbar) VR Training applicable for recurrent training?

Partially. The current module focuses on equipment fundamentals and systematic inspection procedures, which makes it valuable for refreshers on component identification, control functions, and walkaround inspection discipline. Draxon is expanding the Power Stow portfolio, so additional operational and recurrent-focused modules will complement the foundational training in the near future.

Can the Power Stow Rollertrack Conveyor VR Training module help reduce time needed for classroom training?

Yes. Because trainees observe the complete operation cycle and practice walkaround inspections directly in VR with immediate feedback when faults are missed or misidentified, the module can reduce the time spent explaining system components and inspection procedures in theory and increase the time available for higher-value coaching and supervised cargo hold practice.

What are the benefits of the Power Stow Rollertrack Conveyor VR Training for real-world operations?

The module helps trainees internalize systematic inspection routines and recognize safety-critical faults—especially structural damage, missing components, and foreign object debris—without risk to equipment or operations. Understanding all operational controls and safety features before cargo hold work reduces avoidable errors, supports consistent inspection standards across stations, and improves readiness for supervised operational training.

Can people with a tendency to motion sickness do the Power Stow Rollertrack Conveyor VR training?

Yes, most people can complete the Power Stow VR training comfortably. The scenarios are designed around stable cargo hold and parking lot environments with minimal movement and intuitive interactions to keep the experience comfortable while maintaining high training value.

Is the Power Stow Rollertrack Conveyor VR Training aligned with IATA or EASA standards?

Yes, the training design is aligned with EASA safety principles. The Power Stow Rollertrack Conveyor Equipment 101 module incorporates safety-critical routines and standardized inspection procedures—such as systematic walkaround inspections, emergency stop verification, and component fault identification—that reflect the intent of EASA operational training guidance and support safe behavior in cargo hold operations.